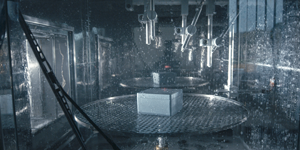

Отделка и сборка

With our extensive machinery and a highly motivated team, we transform our standard products into your individual enclosure solution.

With the complete solution consisting of enclosure, individual machining and assembly, you optimise your supply chain by minimising transport costs and organisational effort. In addition, you can completely exclude possible rejects from your in house processing.

In our assembly department we install following components:

- Terminal blocks

- Cable glands

- Membrane keyboards & decorative foils

- Pressure compensation elements

- Thread bushes

- Gaskets

- Battery compartments

- DIN mounting rails

- Mounting plates

- Connectors

- Spacer bolts

- Earthing connectors

- Bonding of windows and displays

- Tested assembly of supplied components

- Additional fastening possibilities according to your specification

- Assembly and installation of specified cable systems

After all components have been installed, we take over the wiring according to your specification or assemble provided circuit boards.

Our standard enclosures include a seamless polyurethane foam gasket. For special temperature or chemical resistance requirements, we install silicone gaskets. In order to reduce penetration of interference radiation, we can equip our enclosures with EMC gaskets.

If required we test the complete product in our in house laboratory. According to your specification we test the IP protection class (water and dust), corrosion resistance or carry out impact tests. Together we play it safe!

Take advantage of our extensive range of accessories and leave the complete assembly and equipping of your enclosures to us.